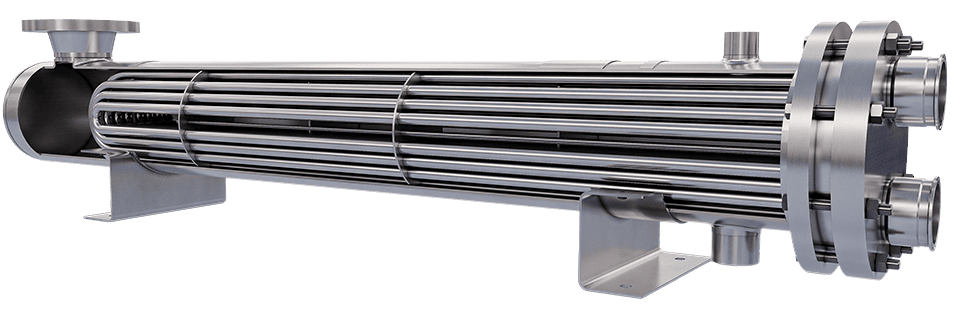

Enerquip Thermal Solutions designs and builds shell and tube heat exchangers trusted across industries—from food and beverage to pharmaceuticals, renewable fuels, asphalt, and chemical processing. Whether you need a readily available stock model or a fully customized solution, our equipment is engineered for efficiency, long-term durability, and compliance with the highest industry standards. Discover the right solution for your process below.

Heat Exchangers for Every Industry

Heat Exchange Solutions Built for Your Process

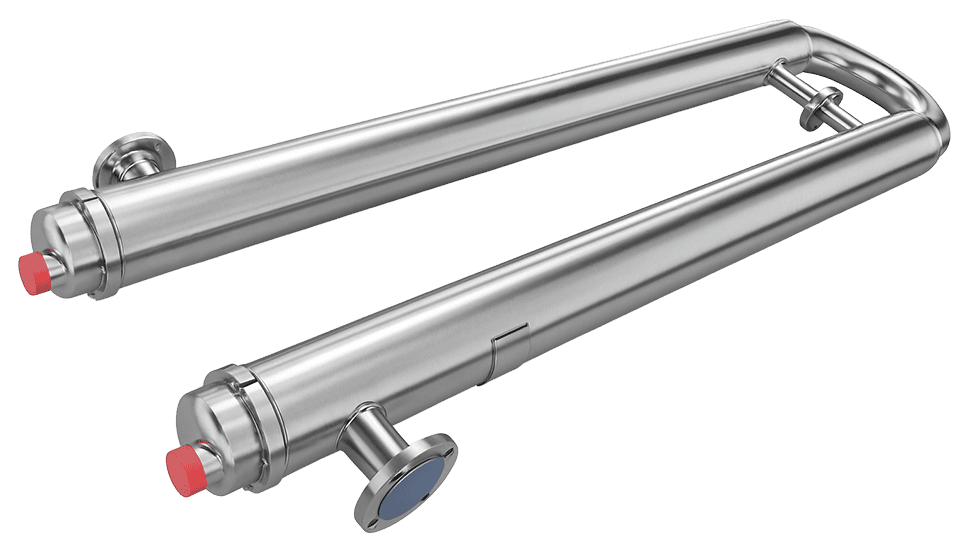

At Enerquip, we design and manufacture a full range of heat transfer equipment to keep your processes running efficiently and reliably. From classic shell and tube heat exchangers to specialized solutions like suction heaters, bayonet heaters, and steam generators, each product is engineered to optimize performance for your unique application. Whether you need to heat, cool, or recover energy, our lineup gives you the flexibility to meet space, pressure, and efficiency demands with confidence.

Common Features of Enerquip's Shell and Tube Heat Exchangers

Our exchangers can be built to your specs with:

- Materials: 304L & 316L stainless steel, carbon steel, Duplex, Hastelloy, Alloy 20, Monel, AL-6XN, and more

- Sizes: Up to 48” in diameter, depending on weight

- Designs: U-tube or straight tube, expansion joints, floating or double tube sheets

- Connections: Sanitary tri-clamp, ASME flanged, or NPT threaded

- Finishes: Passivation, electropolish, polished surfaces for sanitary use

- Compliance: ASME code, TEMA Classes C/B/R, 3-A Sanitary Standards, PED & other international codes

- Maintenance: Removable tube bundles, davit arms, inspection ports, O-rings for easy cleaning

- Accessories: Sight glasses, vacuum breakers, insulation jackets, annular distributors, mounting supports

Learn about industry-specific design features: Sanitary | Industrial | Pharmaceutical

Safety & Compliance

Every exchanger is designed using Compress codeware and reviewed by a third-party inspector. Enerquip exchangers are ASME hydro-tested and built to meet site-specific requirements such as nozzle loadings and seismic considerations. International code compliance (3-A, PED, etc.) is available.

Reverse-Engineered Replacements

Need a drop-in replacement? We can reverse engineer from old drawings, U-1 data reports, or even photos—helping you upgrade to longer-lasting, more corrosion-resistant materials while ensuring fit and performance.

Since 1985, Enerquip has specialized in American-made industrial and sanitary heating and cooling solutions for a broad range of industries. Contact us or request a quote today to find the right process solution for your operation.